With the continuous expansion of China's steel industry and the reduction of domestic iron ore production, imported iron ore gradually occupies an increasingly important position. With the increase of import volume, there have been situations such as short weight, solid waste, impurities, and quality discrepancies, as well as problems such as non-standard declaration by enterprises and unfamiliarity with regulatory policies and processes. Mastering the technical indicators, origin, and mineral types of imported iron ore, familiarizing oneself with customs supervision requirements and processes, is of great significance for ensuring the smooth import of high-quality iron ore and maintaining national security.

Iron ore and its technical indicators

Definition and formation process

Iron ore is abbreviated as iron ore. In theory, any ore containing iron elements or iron compounds can be called iron ore; But in industry or commerce, iron ore not only needs to contain iron components, but also must have utilization value, that is, ores containing economically usable iron elements are called iron ore.

There are two main forms of iron ore formation: one is that iron bearing rocks scattered throughout the earth undergo weathering, disintegration, oxidation, and precipitation to form ore layers with relatively concentrated iron, and then undergo changes such as high temperature and high pressure in the crust to transform them into large-scale iron ores with mining value; Another type is caused by magmatic activity, where magma separates iron minerals when cooled and condensed underground or near the ground, and concentrates in certain areas, interacting with surrounding rocks to form iron ore.

chemical composition

The iron ore in nature is mainly composed of iron containing compounds and gangue. Iron containing compounds include iron dioxide, iron tetroxide, iron carbonate, etc., which are divided into hematite, magnetite, limonite, siderite, etc. according to the different iron compounds they contain; The composition of gangue is mainly silicate. In addition, iron ore also contains various trace elements such as sulfur, phosphorus, lead, arsenic, etc. In the process of steel smelting, they will have adverse effects such as damaging the furnace bottom, reducing softening temperature, and deteriorating the permeability of the material column. However, the cost of removing these harmful elements is high, so the fewer these harmful elements in imported iron ore, the better.

Partial parameter description

Iron content

Iron content is the content of iron element in a unit weight of iron ore, which is the mass fraction of iron element. For example, an iron content of 62 refers to a mass fraction of 62% of iron element, which is the most important parameter for measuring the quality of iron ore and the most important settlement basis in imported iron ore trade. According to the classification of iron content, iron ore is divided into rich ore (with an iron content of over 50%), low-quality ore (35% to 50%), poor ore (25% to 35%), and ultra poor ore.

◎ Moisture content

Moisture is the weight of water contained in a unit weight of iron ore, which is the mass fraction of water. It is generally determined according to ISO 3087 or GB/T 10322.5. For example, the moisture content of a batch of imported iron ore is 8.3 grams, which is equivalent to 8.3 grams of water per 100 grams of iron ore. Moisture is also an important indicator in imported iron ore, which is converted into dry tons for international trade settlement based on moisture. Minor differences in moisture determination within the same delivery batch can have a significant impact on iron ore trading.

◎ Particle size

Particle size is an important indicator for measuring the quality of imported iron ore. In import iron ore trade contracts, both trading parties have detailed regulations on particle size indicators, which are the basis for settlement between iron ore supply and demand parties. There are several forms of expressing particle size specifications in trade contracts: the greater than sign (>), English (up), and symbol (+) can be used to indicate the screened material; The symbol (≤), English (down), and symbol (-) can be used to indicate the sieved material.

Particle size is also a factor that affects the production of steel plants and has a significant impact on the process of blast furnace smelting. If the particle size is too small, it will affect the permeability of the material column in the blast furnace, causing an increase in the resistance of gas rise; Excessive particle size will reduce the contact area between gas and ore, making the central part of the ore difficult to reduce, thereby reducing the reduction rate and increasing the coke ratio, affecting the heating of the furnace charge and the reduction of the ore.

Main production areas and minerals

The main iron ore producing countries in the world include Australia, Brazil, India, Russia, Ukraine, South Africa, Venezuela, and other regions. According to conditions such as import volume and target steel mills, China's imported iron ore can be divided into mainstream and non mainstream mines. The mainstream ore mainly refers to iron ore from Australia and Brazil. Among them, the majority of imported iron ore is produced in Australia, mainly in the Pilbara and Hamsley regions; Secondly, it comes from Brazil, with the main production areas being Tiesijiao and Karagas regions. The iron ore reserves in these production areas are huge, with stable quality. The ore is mainly open-pit rich ore that is easy to mine, and transportation conditions such as railways and ports are complete.

Others are non mainstream mines, such as Bihar and Olisa regions in India, Korivorogo regions in Ukraine, Bolivar regions in Venezuela, and Kursk regions in Russia. These imported iron ore production areas have small reserves, many mines, and belong to many small companies. Many imported iron ores are mixed and shipped from multiple mines, resulting in significant quality fluctuations.

The iron ore produced in different regions and mines has different indicators such as iron content, element content, color, sintering performance, hardness, etc., which divides iron ore into many specific species, abbreviated as ore types. There are many species of iron ore, and currently, more than 100 types of ore have been discovered.

Iron ore clearance

ax rate

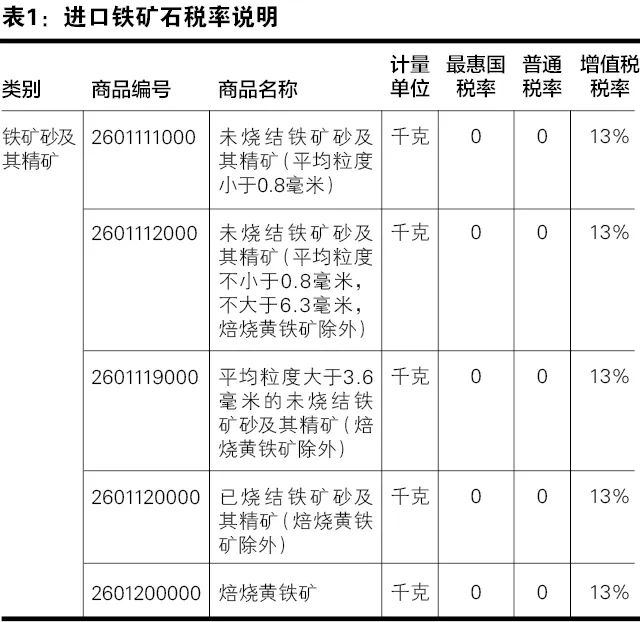

At present, among the main source countries of iron ore, the most favored nation tax rate and ordinary tax rate for import tariffs are both 0, and the value-added tax rate is 13%, as shown in Table 1.

图片来源:中国海关杂志

图片来源:中国海关杂志

Standardized declaration

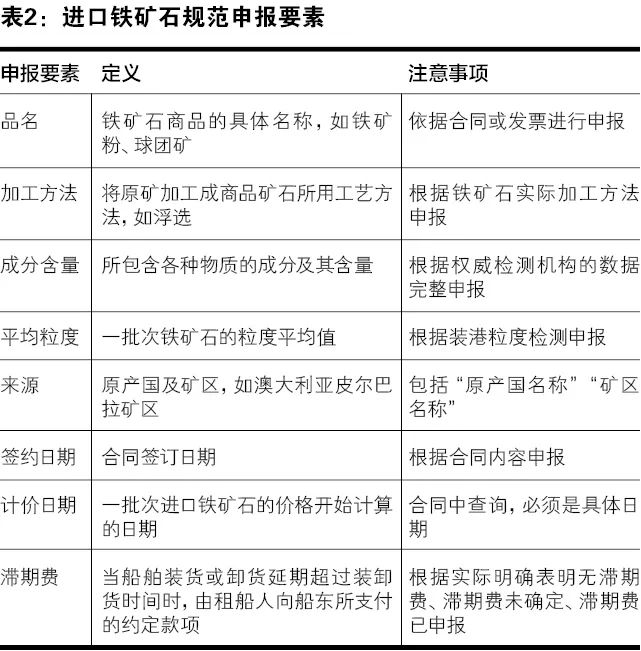

The import of iron ore mainly involves goods under tariff item 2601 of the Import and Export Tariff of the People's Republic of China. According to the latest revised 2022 version of the Catalogue of Customs Import and Export Commodity Norms, the common declaration elements for the above tariff items are shown in Table 2.

图片来源:中国海关杂志

图片来源:中国海关杂志

Entry inspection and supervision

Regulatory methods

Quality inspection

According to the Announcement on Adjusting the Supervision and Inspection Method for Imported Iron Ore, the customs has adjusted the supervision and inspection method for imported iron ore from batch by batch sampling quality inspection to implementation based on enterprise applications. If an enterprise applies for inspection, the customs shall issue a certificate in accordance with the application for inspection.

Weight identification

If there are no special regulations, for imported iron ore in bulk by sea, a water gauge weighing method can be used; For those who do not have the conditions for measuring weight with a water gauge, a weighing instrument will be used for weighing. According to the Announcement on Adjusting the Supervision Method of Weight Appraisal for Imported Bulk Commodities, the implementation of weight appraisal for imported bulk commodities in batches will be adjusted to be implemented by the customs according to the application of enterprises, and if necessary, the customs will implement it according to their authority.

Inspection requirements

◎ Inspection and quarantine of foreign inclusions

During the unloading process, customs conduct inspections. If any restricted foreign objects, such as weeds, seeds, etc., are found, they will be photographed and archived, and sent to relevant laboratories for testing or identification. Customs will require shippers to pick up and classify mixed waste such as household waste and plastic waste, and suspend unloading. The customs shall propose corresponding handling plans based on specific circumstances, such as quarantine treatment or return, and shall implement them after being reviewed and approved by the superior competent department.

Radiological testing

According to the requirements of the "Regulations for Radioactive Inspection of Imported Mineral Products" (SN/T 1537), customs shall conduct inspections on iron ore at the place of entry γ Radiation dose rate on-site testing. When discovered in the goods γ When the radiation dose equivalent rate is 10 times higher than the local environmental radiation background value, the goods are considered unqualified.

Solid waste screening

During the unloading process, customs conduct solid waste screening on imported iron ore, conducting sensory inspections based on its color, shape, odor, density, and other characteristics, and using solid waste rapid screening equipment for auxiliary inspection. If there are no abnormalities, release them; If it is believed that there is an abnormality, sampling and inspection shall be carried out according to the "Identification Procedure for Solid Waste Properties of Imported Goods", and the identification results shall be issued by a qualified laboratory for subsequent processing.

Sampling and testing

According to the regulatory requirements for imported iron ore, if the shipper applies for inspection, the customs will implement sampling and testing, and issue a quality certificate.

At present, iron ore sampling is mainly divided into manual sampling and mechanical sampling. Manual sampling is carried out in accordance with standards such as SN/T 1797.1-2008, and systematic sampling is carried out throughout the unloading process; Mechanical sampling refers to the use of large-scale combined machinery to regularly and quantitatively take samples during the unloading process of iron ore, while meeting the parameter requirements of GB/T 10322.1-2014.

After the sampling of iron ore is completed, the sample is subjected to a series of operations such as mixing, shrinkage, moisture detection, particle size detection, crushing, and grinding to obtain the moisture content and particle size composition. Analysis samples below 0.1 millimeters are made and sent to the laboratory for testing. According to current standards such as GB/T 6730.5, the content of total iron, sulfur, silicon dioxide, aluminum oxide, phosphorus, etc. is measured, and an inspection report is issued.

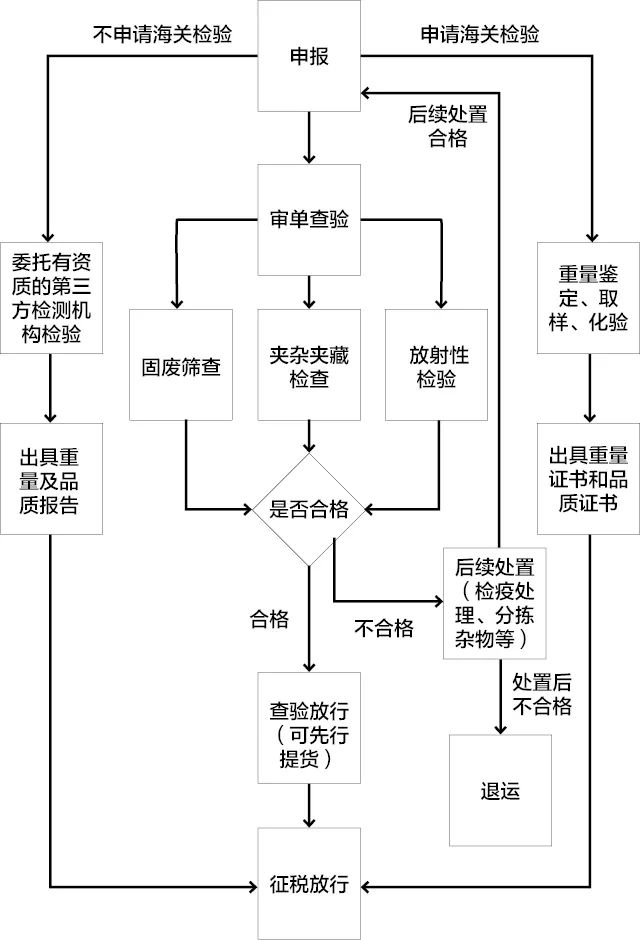

Regulatory process

After declaring a shipment of imported iron ore, the customs will conduct on-site inspections such as solid waste screening, and conduct weight identification and sampling analysis based on whether to apply for inspection. For situations that belong to solid waste or exceed radioactive standards, the customs will handle the return and impose penalties in accordance with regulations; Those that pass the inspection will be transferred to the customs department for taxation and release, as shown in the following figure.

Image source: China Customs Magazine

Image source: China Customs Magazine

Source: Souhang Network